The leaf pellet machine can use leaves as raw material and transfer then to fuel pellets. After leaves being crushed, they are pressed into fuel pellets and used as fuel for boilers or small household stoves.

Leaves are light and loose, and have a very low bulk density, especially after being crushed. When choosing a pellet machine, if you want to produce high-density fuel pellets, then no matter what types the pellet machine is, a hard-toothed reducer is a must, because when pressing these low-density raw materials, the mold compression ratio is large, the resistance is large, and the pressure required is large. Therefore, it is a challenge for the transmission device . The hard-toothed reducer can maintain an extremely low failure rate and reduce block risks.

Generally speaking, most biomass pellet machines are equipped with a screw feeder, because screw feeders have less dust problem. However, when your raw material has a very low bulk density, or the fiber toughness after crushing is relatively strong, or the size is still relatively large after crushing, do not choose a screw feeder, because this will greatly reduce the output of the biomass pellet mill, and the raw material may cause machine block. The screw feeder of the pellet machine is more suitable for raw materials with high density and good fluidity, and the crushed leaves obviously do not have these characteristics.

Compared with the commonly used wood sawdust, leaves often contain more soil and other impurities, which will greatly increase the wear of the pellet machine ring die and the press rollers. In order to increase the service life of the wear parts, we recommend you using the stainless steel ring die and the welding types wear-resistance to press rollers to ensure the service life. Although the cost of the will be slightly higher, the actual production cost if each ton pellets is lower.

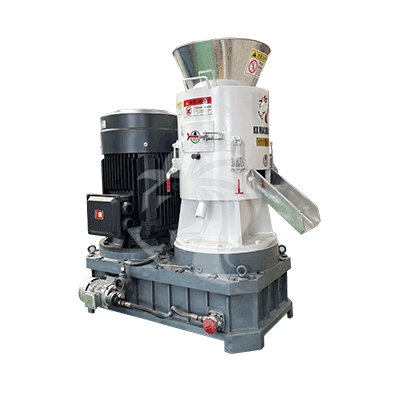

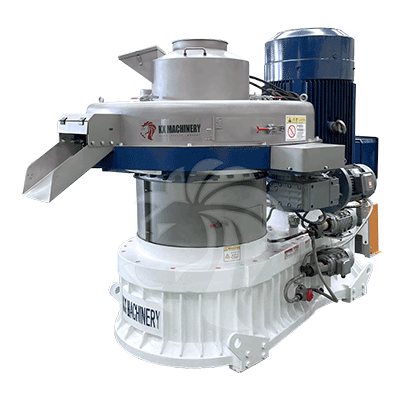

| MACHINE TYPE | FLAT DIE PELLET MACHINE | RING DIE PELLET MACHINE |

| ELECTRIC MOTOR | 7.5-75KW | 55-280KW |

| PELLET DIAMETER | 3mm-10mm | 3mm-10mm |

| MACHINE OUTPUT | 80-1,100KG/H | 600-4,000KG/H |

| APPLICATION | SMALL BUSINESS | INDUSTRIAL APPLICATION |

The leaf pellet mill is an incredibly versatile solution for processing a wide variety of leaves into high quality biomass pellets. Its design allows it to handle diverse types of raw materials, making it an excellent choice for industries looking to recycle organic waste into sustainable energy.

Our machine is aim to process various types of leaves, including:

Whether you want to deal with agricultural residues, forestry waste, or seasonal leaf fall, this commercial pellet machine efficiently turns these materials into dense, uniform pellets.

Many new users just entering this field may have some questions as followed:

The answers are: there is no difference in pellet density no matter it’s from small flat die pellet mill or from the large ring die pellet machine. Both machines can produce pellets with a density of 1.1-1.3g/cm³ and the pellet forming rate over 99%. That’s because the machines are equipped with same heavy-duty gear boxes, ensuring sufficient pressure to produce high-quality biomass pellets consistently.

Please share details about your raw materials and capacity, and if possible, include photos of the raw materials. It will help us the know better about the material size and moisture content. With this information, we can recommend the most suitable pellet machine for your needs, ensuring efficient production and high-quality pellets. We’re here to help you make the right choice and get the best return on your investment.

PELLETS FROM FLAT DIE PELLET MILL

PELLETS FROM RING DIE PELLET MACHINE

For optimal pellet production, the moisture content of leaves should be around 15%. If the moisture is too high, it may affect pellet quality and lead to operational issues. If it’s too low, it could result in poor compression and lower output.

Yes, especially when you choose a flat die pellet mills. It’s very easy to do maintenance, only thing you need do is doing lubrication ever shift, and replace the flat die and press rollers every a few months.

With proper maintenance, the lifespan of the leaf pellet machine can be many years. The heavy-duty design and durable components ensure reliable performance over time, even under continuous use.

Sure, in addition to leaves, the biomass pellet machine can process a variety of other biomass materials such as straw, grass, sawdust, and other agricultural residues, just change the different die, then could make for other biomass pellet production.

Office – A2, Chuangzhigu Zone, Shandong, 256400, China.

86-0533-8680080

info@ecopelletmills.com